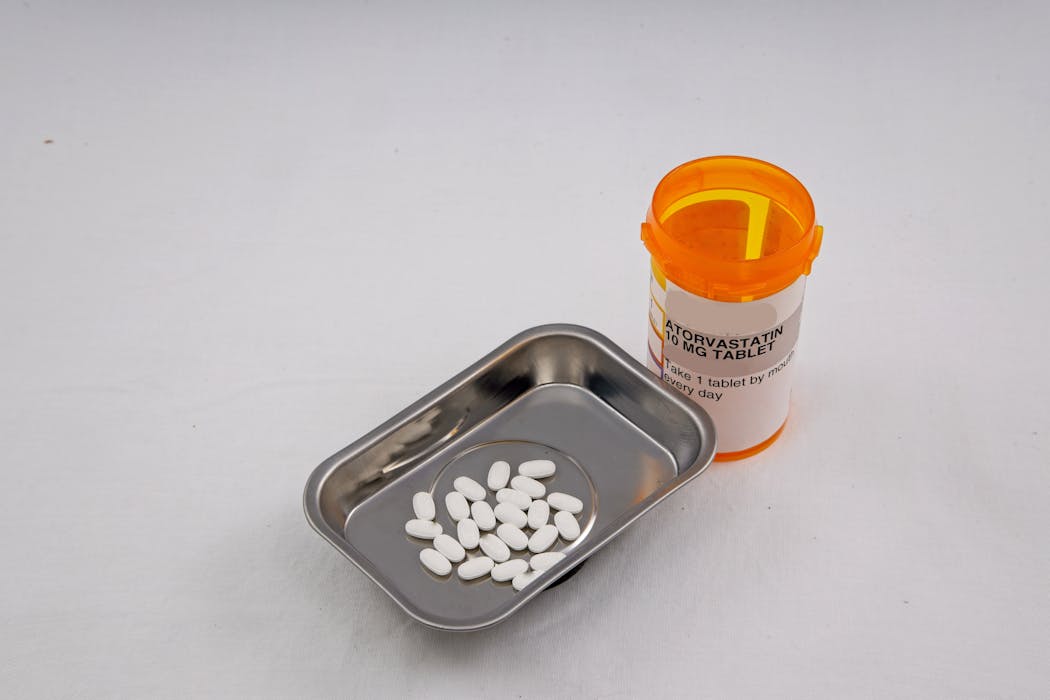

If you take cholesterol-lowering drugs called statins, you may have noticed a flurry of news coverage since late October 2025 about an extensive recall of thousands of bottles of atorvastatin, the generic version of Lipitor.

Both generic atorvastatin and brand-name Lipitor contain the same active ingredient, atorvastatin calcium, and are considered bioequivalent by the Food and Drug Administration. This medication is the No. 1-selling drug in the U.S., with over 115 million prescriptions going to more than 29 million Americans.

I am a clinical pharmacologist and pharmacist who has assessed the manufacturing quality of prescription, over-the-counter and illicit drugs, as well as dietary supplements.

This atorvastatin recall is large, potentially affecting hundreds of thousands of patients. But it’s only the latest in a series of concerning manufacturing issues that have come to light since 2019.

What pills are being recalled, and why?

Ascend Laboratories, based in New Jersey, originally issued the recall for about 142,000 bottles of its generic atorvastatin on Sept. 19. Each bottle contained 90, 500 or 1,000 tablets, enough to fill prescriptions for three, 17 or 33 patients, respectively, for one month.

About three weeks later, on Oct. 10, the FDA quantified the risk of using these poor-quality tablets and gave the recall a Class II status, which means that the medication could cause “temporary or medically reversible adverse health consequences.”

Manufacturers must conduct quality tests on random samples of tablets from every batch they make. These tests make sure the pills contain the correct dosage of the active ingredient, are made to the proper physical specifications and are not contaminated with heavy metals or microbes. If the samples test “out of specification” for any feature, the company must conduct further testing and destroy defective batches, losing the cost of manufacturing them.

In this case, sample pills failed to dissolve properly when they were tested. Batches manufactured from November 2024 through September 2025 all had this defect.

As with other drugs, when you swallow atorvastatin, it must dissolve before the active ingredient can be absorbed by the body. It then goes to the liver, where it reduces the blood concentrations of low-density lipoproteins – also called LDL, or “bad cholesterol.”

If the drug doesn’t dissolve properly, the amount absorbed by the body is substantially reduced.

Lowering LDL with atorvastatin has been shown to reduce cardiovascular events like heart attacks and strokes after a few years by 22%. When almost 30,000 people in a 2021 study stopped taking their atorvastatin or other statin for six months, the risk of cardiovascular events, deaths and emergency room visits increased between 12% to 15%.

So, while patients wouldn’t immediately feel a difference if their atorvastatin tablets didn’t dissolve properly, their risk of cardiovascular events would significantly rise.

What should patients on generic atorvastatin do?

First, don’t stop taking the medication without talking with your pharmacist or prescriber. Even if you have the recalled pills, taking them is still better than not taking the medicine at all.

You can determine whether your medication came from Ascend Laboratories by looking at your prescription label.

Search for the abbreviations MFG or MFR, which stand for “manufacturing” or “manufacturer.” If it says “MFG Ascend” or “MFR Ascend,” that means that Ascend Laboratories supplied the medication.

The first five letters of a National Drug Code, abbreviated as NDC on the prescription label, also reveal the manufacturer or distributor. Ascend products have the number 67877.

If Ascend Laboratories is the distributor, a pharmacist can cross-reference your prescription number to obtain the lot number and compare it with the posted lot numbers on the FDA website for recalled atorvastatin. If your product has been recalled, your pharmacy may have other generic versions of atorvastatin in stock that are not part of this recall.

Alternatively, the pharmacist can get a new prescription from your health care provider for another generic statin drug, such as rosuvastatin, which works similarly.

A pattern of lapses for overseas manufacturers

While the defective atorvastatin is distributed by a U.S. company, it is actually manufactured by Alkem Laboratories in India.

In fact, many aspects of pharmaceutical drug manufacturing are now occurring overseas, primarily in China and India. This has limited the FDA’s ability to provide the oversight required for drugs sold in the U.S.

In the 1990s and early 2000s, the FDA performed routine surveillance inspections of U.S. manufacturing plants every three years, but seldom conducted them overseas. In the wake of several high-profile manufacturing quality lapses, including at the Indian generic drug giant Ranbaxy Laboratories, Congress established a funding mechanism and the FDA established a universal standard for inspecting both U.S. and overseas manufacturers every five years.

However, the U.S. fell behind with international inspections after COVID-19 shut down international travel, and it has yet to catch up. Additionally, overseas manufacturers generally get warning of an upcoming inspection, making the process potentially less rigorous than in the U.S.

A lack of inspections for eye drop manufacturers, especially in India, led to massive recalls in 2023 after a wave of rare eye infections caused some people to lose their eyesight. The problem was traced to widespread unsanitary manufacturing conditions and improper testing for sterility at overseas facilities.

In 2024, eight deaths and multiple hospitalizations led an Indian manufacturer, Glenmark Pharmaceuticals, to recall 47 million potassium chloride extended-release capsules that did not dissolve properly. In February 2025, inspectors found that the company had falsified quality results.

The FDA recently started laboratory spot testing of prescription and over-the-counter drugs arriving in the U.S. to compensate for these limitations. Outside laboratories such as Valisure also do independent testing. Independent testing has caught several dangerous products, but due to limited resources, only a few products can be tested each year.

In 2023, Alkem Laboratories, which manufactured the currently recalled atorvastatin, had to recall 58,000 bottles of the blood pressure drug metoprolol XL because the pills also did not properly dissolve. Spot testing also led to widespread recalls after FDA and Valisure laboratories found cancer-causing chemicals called nitrosamines in some blood pressure, diabetes and indigestion drugs tested between 2019 and 2020, as well as benzene in numerous sunscreen and antibacterial gel products tested between 2020 and early 2025.

Raising consumer vigilance

With these growing gaps in oversight, it’s reasonable to be mindful of changes in how a particular medication affects you. If your prescription drug suddenly stops working, it might be because that particular batch of the medication was not manufactured properly. Alerting the FDA about sudden loss of drug effectiveness could help the agency more quickly identify manufacturing issues.

In 2024, the FDA started sharing the inspection burden with other regulatory agencies like the European Medicines Agency for the European Union. Such coordinated efforts could lead to less duplication and a bump in inspections of overseas manufacturers.

In the meantime, however, consumers are largely at the mercy of spotty inspections and testing, and rarely hear about problems unless poorly manufactured drugs cause widespread adverse events.

This article is republished from The Conversation, a nonprofit, independent news organization bringing you facts and trustworthy analysis to help you make sense of our complex world. It was written by: C. Michael White, University of Connecticut

Read more:

- The silent threat of the coronavirus: America’s dependence on Chinese pharmaceuticals

- The FDA’s weak drug manufacturing oversight is a potentially deadly problem

- Recent drug shortages in Europe overshadow half a century of trade surpluses

C. Michael White does not work for, consult, own shares in or receive funding from any company or organization that would benefit from this article, and has disclosed no relevant affiliations beyond their academic appointment.

The Conversation

The Conversation

Raw Story

Raw Story People Human Interest

People Human Interest KCCI 8

KCCI 8 The Cut

The Cut AlterNet

AlterNet Citizen Tribune

Citizen Tribune FOX News Videos

FOX News Videos